In 1991, Arla Foods Inc. (Arla) — a global leader in specialty cheese — partnered with Amalgamated Dairies Limited (ADL) in Prince Edward Island to bring locally produced Havarti and Feta to Canadian consumers.

This collaboration blended Arla’s global cheese-making expertise with ADL’s deep local knowledge in dairy processing, resulting in products that proudly emphasize freshness, authenticity, and quality.

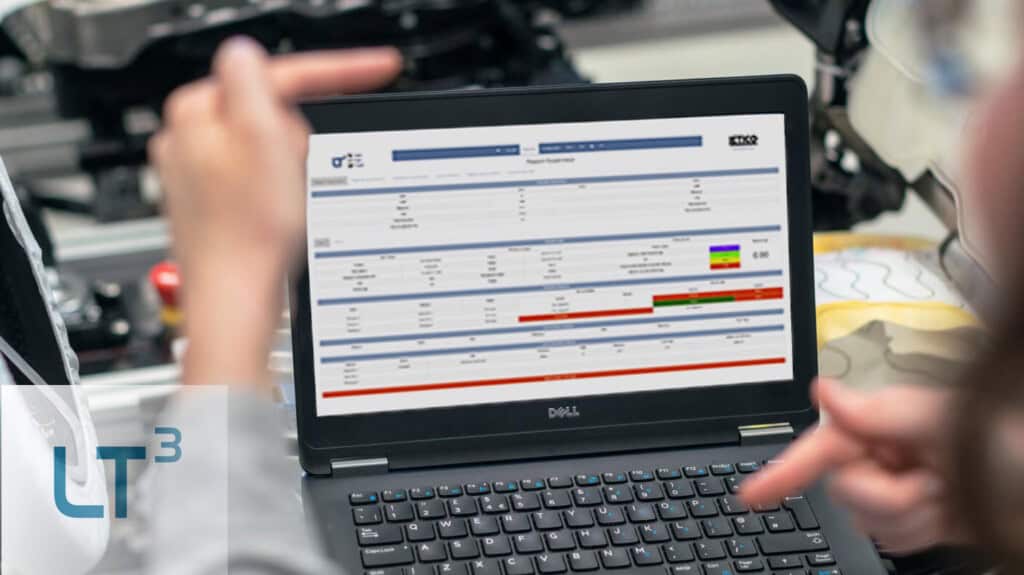

In 2024, ADL-Arla achieved a reduction in giveaways representing nearly 2% of the total weight of cheese , which is a lot of savings, easily proving the business case for LT³. Letico also reviewed the data and, based on LT³’s comprehensive integration, recommended further improvements to the line for even greater efficiency. ADL-Arla is considering expanding use of LT³ on additional lines.

The installation of LT³ brought a host of advantages to ADL Summerside facility: