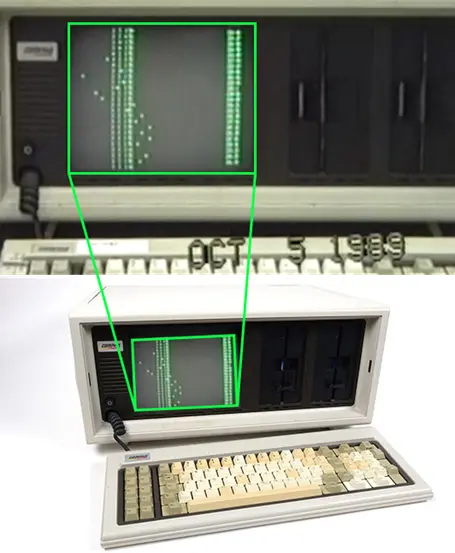

Original weight tracking software programmed by Letico for the Ingleside facility in 1989.

In the 1980s, giveaway control relied on small sample sizes, manual adjustments, and operator judgment, which was effective but limited. Letico saw an opportunity to bring industrial automation to weight control: measure every unit, automate adjustments in real time, and transform weight tracking into a powerful optimization tool. As the system evolved, new challenges followed:

2010–2013: LT³ precursor built by Letico “MyWeights” introduces database logging, trending, and virtual infrastructure. Ingleside staff rely on MyWeights to achieve optimal performance.

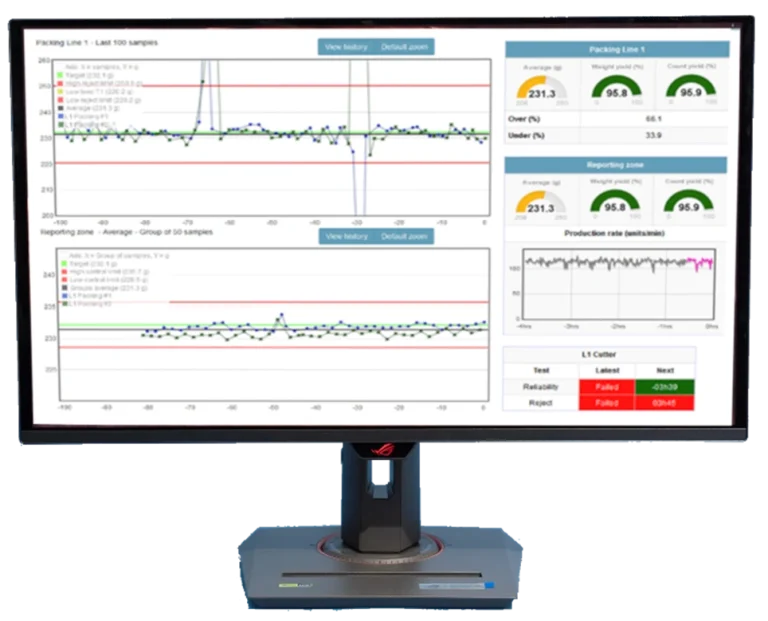

LT³ delivers a scalable leap forward in production line optimization and process control: it links data from all PLCs and industrial communication systems such as Modbus and Profibus. This flexibility ensures compatibility with legacy and modern equipment alike, simplifying system integration and production line optimization across multiple facilities.

Once installed, it measures every piece by position in sequence and optimizes line performance across multiple variables for maximum payback.

AI-driven feedback now makes LT³ accessible to a broader range of experience, empowers new teams and shifts the focus from reactive to predictive.

2014: Letico launches LT³ (Letico Track, Trace & Target) as a scalable performance platform.

2017: Ingleside adopts LT³, transforming daily operations.

Born in 1989 as a simple visibility tool, LT³ has evolved into a corporate-wide industrial automation and performance engine. At Lactalis, actionable data and efficiency gains continue to keep Ingleside at the forefront of dairy production.